Oil contamination in compressed air is a serious concern for many manufacturers. With options like food-grade oil, and oil-free compressors, many are left wondering if what they are doing is enough to prevent contamination from reaching their end products. The best way to ensure that filtration, maintenance, and preventative measures are working properly is to test. With the compressed air experts at Trace Analytics, it is easy to meet your requirements and gain an understanding of the quality of your compressed air. Watch the original webinar on Total Oil Analysis here.

Who Defines and Guides the Compressed Air Industry?

There are a variety of regulating bodies and certifying bodies that set out specifications and limits regarding compressed air quality.

– SQF

– BRCGS

– FDA

– GFSI

– FSSC

These requirements are often vague, leaving most of the decisions up to the user. Many of these guidelines and industry leaders point to the international compressed air standard: ISO 8573. This standard provides limits and explains how sampling and analysis should be completed. Trace Analytics provides testing that complies with ISO 8573.

Where Does Total Oil Contamination Come From?

The main sources of contamination for oil are ambient air (vehicular exhaust, other manufacturing processes etc.), the air compressor itself (lubricants and oils), the heating and cooling of the air receiver, distribution piping (leaks, drops, etc.), and malfunctions (separator filter, light loading, clogged oil returns etc.).

Just because you can’t see the oil, does not mean it’s not there. Further, even if you have an oil-free compressor, it is still imperative that you test for oil. The only way to guarantee that your system is meeting the quality requirements is to perform risk assessments, regularly monitor the system, and perform preventative maintenance.

What is Total Oil?

According to ISO 8573, oil is defined as a mixture of hydrocarbons composed of C6+ atoms. Oil in a compressor system is used to reduce typical wear and tear, and help with cooling, sealing, and cleaning. Be wary of universal oils and lubricants – use what’s right for your usage.

Total Oil and Purity Class Considerations

If you are unsure about what purity classes to choose for Total Oil, you can always ask for a Baseline or Diagnostic test. Alternatively facilities can perform a risk assessment with their quality managers to determine which purity classes are appropriate for their needs. A downloadable risk assessment is available here.

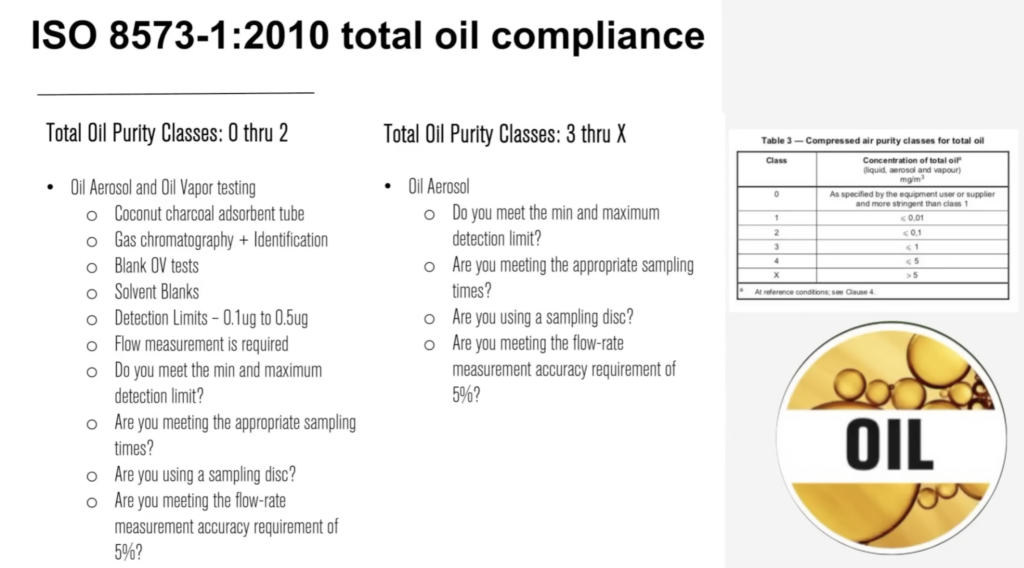

When testing to ISO 8573, Classes 1 and 2 require both testing for oil vapor and oil aerosol. It’s essential that your laboratory has the ability to test for both. Class 3 and 4 require only aerosol testing. Vapors are known to be present in these samples, but they don’t make a nominal difference at the limits stated by classes 3 and 4.

How to Test for Total Oil

Given that total oil requires testing for oil aerosol and oil vapor, ISO 8573 outlines methods for both types of oil. Part 2 of 8573 outlines either full flow or partial flow methods.

Quantification methods for oil aerosol:

– Sampling disc gravimetry

– Gas Chromatography FID

– Infrared Spectroscopy

Part 5 of the standard outlines oil vapor requirements. Oil Vapor samples are collected using a coconut charcoal adsorbent tube.

Quantification methods for oil vapor:

Gas chromatography

Oil vapor tests include controls, field blanks, daily calibrations, full scan spectra, and a NIST Traceable library for identifying compounds. Trace Analytics both quantifies and identifies compounds in oil vapor samples. This is particularly helpful as it allows for more in depth troubleshooting.

Total Oil Compliance Checklist

Other Oils

In addition to C6+ hydrocarbons, some users may be interested in their gaseous TVHC contaminants. These are hydrocarbons C1-C5 which are lighter oil compounds. These are sampled via source bottle and analyzed via GC/FID.

Conclusion:

Total oil testing is an important part of a facilities monitoring program and should be completed with a third party lab who can provide the appropriate sampling materials and facilitate analytical methods dictated by ISO 8573. Contact our experts at Trace Analytics for more information on getting started with Total Oil testing.

Watch the original webinar presented by IFSQN.com.