Food Grade Air in Manufacturing

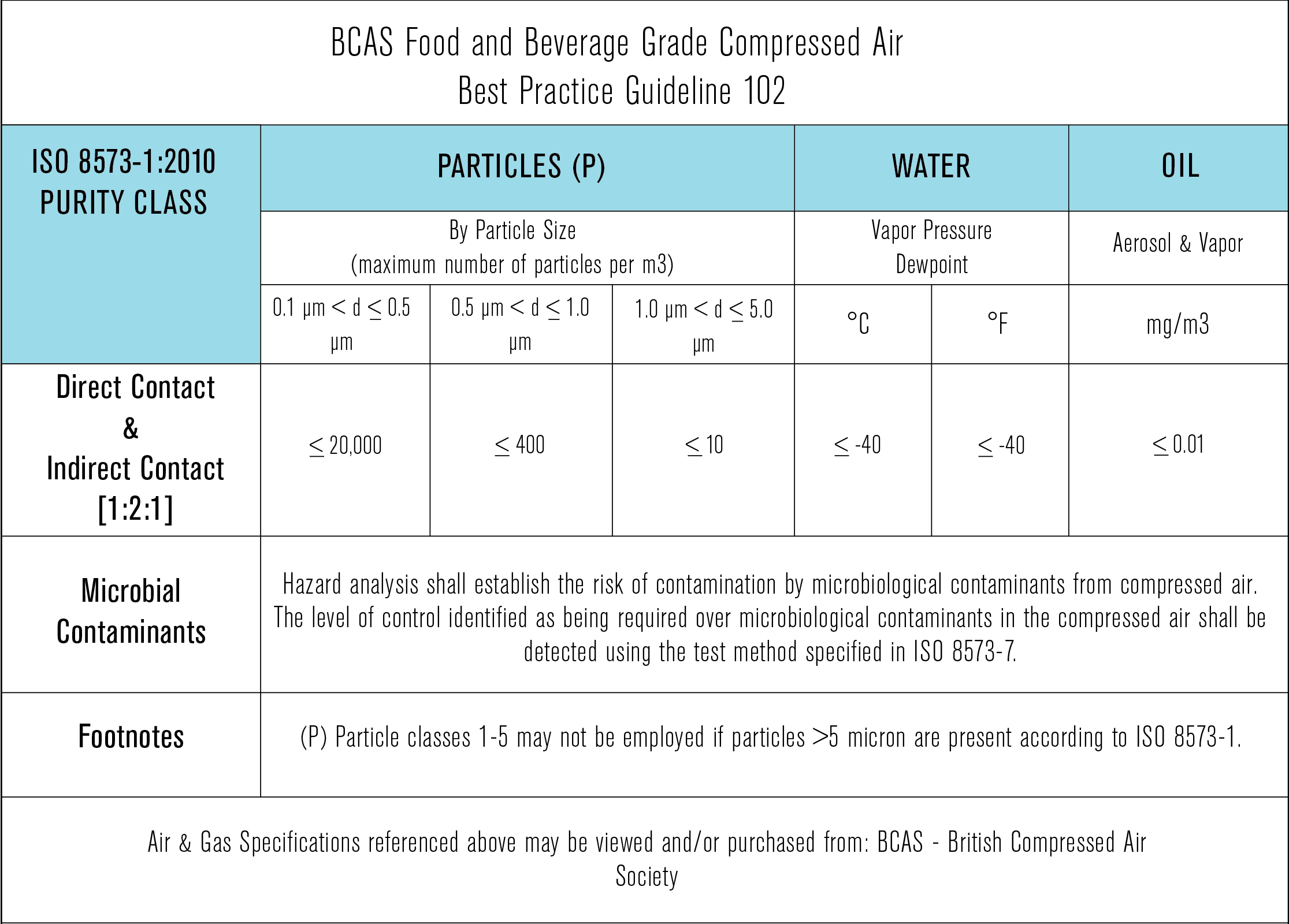

The British Compressed Air Society (BCAS) Food and Beverage Grade Compressed Air Best Practice Guideline 102 is an excellent reference for the food manufacturer and its suppliers. The BCAS Best Practice Guideline identifies the four primary areas of potential contamination in compressed air – Particles, Water, Oil, and Microbiological Contaminants. Section 7 of the Guideline states that compressed air coming in Direct or Indirect Contact with food shall meet ISO 8573-1:2010 Purity Class 1:2:1. See Table below for limits.

Food Grade Air in Manufacturing Compressed Air & Gas Testing Specifications

Trace Analytics, LLC is an A2LA Accredited Laboratory in compliance with ISO 17025 as required by BRC and SQF. We can test to a wide variety of specifications. Some example specs commonly used in Food Grade Air in Manufacturing are shown at the bottom of the page.

According to the Guideline, compressed air quality shall be tested and verified at least twice per year or per the manufacturer’s recommendations. Additional testing is also warranted whenever maintenance work or any activity that may affect the air quality is performed on the compressed air system. (Section 8.2) The Guideline recognizes the importance of compressed air quality and states that compressed air should now be part of the Pre-Requisite Program (PRP) in addition to the Hazard Analysis & Critical Control Points (HACCP) plan. (Section 4) Whenever maintenance is performed a representative selection of the air outlets shall be tested to confirm that the compressed air meets the relevant Purity Classes. (Annex D.4) The risk for microbiological contaminants shall be assessed per ISO 8573-7. It further states that microbiological testing of end products should not be relied upon for compressed air compliance. (Section 7.4) All measurements shall be recorded and documented. (Section 8.7)

The International Featured Standards on Food (IFS) states, the quality of compressed air that comes in direct contact with food or primary packaging material shall be monitored based on hazard analysis and assessment of associated risks. (Section 4.9.10.1) And compressed air shall not pose a risk of contamination. (Section 4.9.10.2)

The Global Aquaculture Alliance states in its Best Aquaculture Practice (BAP), all critical control points must be properly identified in order to control hazards. (Section 5.2.4) And monitoring must be adequate to control hazards and carried out as detailed in the HACCP plan. (Section 5.2.11)

The Global Red Meat Standard (GRMS) states, hazards relevant to food safety shall be controlled in critical control points (CCP) and/or by GMP measures. (Section 12.1.2) And relevant parameters shall be selected for monitoring every CCP and these must be capable of demonstrating the conformity of the control measure. (Section 12.4.3)

PrimusGFS states that verification plans and schedules shall be developed for each CCP. (Section 3.03)

A periodic compressed air test program can provide critical information about your air quality and help prevent contamination of the food supply. Due to the critical nature of compressed air used in the food manufacturing process, qualified personnel should be employed to properly maintain, service, and test the compressed air system.

We offer baseline testing when you are unsure what Purity Classes your air system can meet, we can also provide analysis for any given Purity Classes you select, or you can provide your own custom specifications. Trace’s AirCheck✓ Kit™ K810 can be used to sample for particles, water, and oil (aerosol and vapor); Model KPSII is available for microbial sampling.