Pet Food Compressed Air Testing

Compressed air used in the manufacturing process of pet food should be considered a Critical Factor as it can have a direct affect on the Commercial Sterility of the final product. Assuring pet food compressed air safety and quality is essential for the viability of any pet food manufacturer.

Pet Food Industry

Compressed Air Testing

The Food and Drug Administration (FDA) regulates the pet food industry. The Federal Food, Drug and Cosmetic Act (FFDCA), requires that all animal foods, like human foods, be safe to eat and contain no harmful substances. Compressed air used in the manufacturing process of pet food should be considered a Critical Factor as it can have a direct affect on the Commercial Sterility of the final product. Assuring pet food safety and quality is essential for the viability of any pet food manufacturer.

Compressed air quality in pet food manufacturing should be tested and verified and additional testing is warranted whenever maintenance work or any activity that may affect the air quality is performed on the compressed air system. It is suggested that a representative selection of the air outlets shall be tested to confirm that the compressed air meets the relevant Purity Classes noted in the Table above.

A periodic air test program can provide critical information to monitor air quality and help prevent contamination of the pet food supply. Due to the critical nature of compressed air used in the pet food manufacturing process, qualified personnel should be employed to properly maintain, service, and test the compressed air system.

We offer baseline testing when you are unsure what Purity Classes your air system can meet, select Purity Classes from the current ISO 8573-1:2010 specs below, or provide your own custom specification.

Pet Food Compressed Air & Gas Standards

| ISO 8573-1:2010 COMPRESSED AIR CONTAMINANTS AND PURITY CLASSES | ||||||||

|---|---|---|---|---|---|---|---|---|

| CLASS | PARTICLES | WATER | OIL | |||||

| By Particle Size (maximum number of particles per m3) See Note 2 |

By Mass | Vapor Pressure Dewpoint | Liquid | Liquid, Aerosol, & Vapor See Note 1 |

||||

| 0.1 µm < d ≤ 0.5 µm | 0.5 µ m< d ≤ 1.0 µm | 1.0 µm < d ≤ 5.0 µm | mg/m3 | °C | °F | g/m3 | mg/m3 | |

| 0 | As specified by the equipment user or supplier and more stringent than class 1 | |||||||

| 1 | ≤ 20,000 | ≤ 400 | ≤ 10 | - | ≤ -70 | ≤ -94 | - | ≤ 0.01 |

| 2 | ≤ 400,000 | ≤ 6,000 | ≤ 100 | - | ≤ -40 | ≤ -40 | - | ≤ 0.1 |

| 3 | - | ≤ 90,000 | ≤ 1,000 | - | ≤ -20 | ≤ - 4 | - | ≤ 1 |

| 4 | - | - | ≤ 10,000 | - | ≤ +3 | ≤ +37 | - | ≤ 5 |

| 5 | - | - | ≤ 100,000 | - | ≤ +7 | ≤ +45 | - | - |

| 6 | - | - | - | 0 – ≤ 5 | ≤ +10 | ≤ +50 | - | - |

| 7 | - | - | - | 5 – ≤ 10 | - | - | ≤ 0.5 | - |

| 8 | - | - | - | - | - | - | ≤ 5 | - |

| 9 | - | - | - | - | - | - | ≤ 10 | - |

| X | - | - | - | > 10 | - | - | > 10 | > 5 |

| MICROBIOLOGICAL CONTAMINANTS | OTHER GASEOUS CONTAMINANTS | |||||||

| No purity classes are identified | No purity classes are identified Gases mentioned are: CO, CO2, SO2, NOX, Hydrocarbons in the range of C1 to C5 |

|||||||

| Note 1: ISO 8573 Oil includes aerosol, vapor in the range of C6+, and liquid oil. Liquid oil is typically sampled when wall flow is present, contamination is suspected, or results are greater than 5 mg/m3. Trace can provide a separate kit for liquid oil testing. Note 2: For Particle Class 0, 1, & 2 (0.1 - 0.5 µ range only), a laser particle counter with a high-pressure diffuser is required. Rental of this equipment is available on a reservation basis. Contact us for details. To qualify for Particle Classes 0 through 5, there can be no particles greater than 5µ present. In some cases, Trace uses alternative sampling techniques or analytical methods to those specified in ISO 8573, for details see Smith White Paper, 2012. |

||||||||

| Air & Gas Specifications referenced above may be viewed and/or purchased from: ANSI - American National Standards Institute |

||||||||

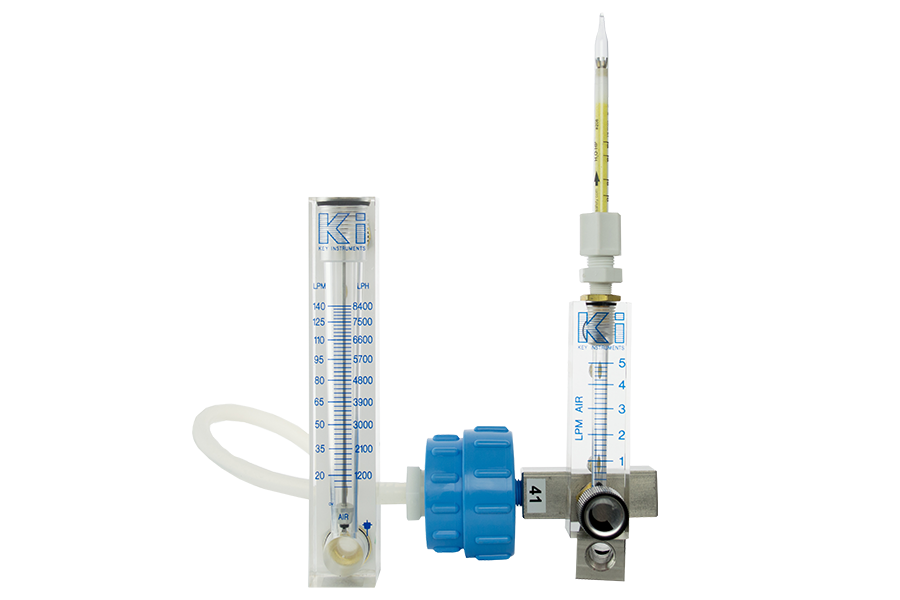

AirCheck Kits Available

K810 AirCheck Kit for Manufacturing

The AirCheck✓ Kit™ K810 is designed for use with manufacturing specifications such as ISO 8573, and other custom specifications testing for particles, water, and total oil. This kit is typically used by food manufacturers, pharmaceutical manufacturers, medical device facilities, and nuclear plants who use low pressure air in their processes and systems. Test from the compressor or point of use. Watch our online sampling video for kit instructions.

Why Choose Trace Analytics?

Meet Requirements

ISO 8573 identifies the three primary areas of potential contamination in compressed air – Particles, Water, and Oil. In the human food industry, compressed air coming in Direct or Indirect Contact with food needs to meet ISO 8573-1:2001 Purity Class 1:2:1.

Meet your pet food compressed air requirements.

Online Reports and Tools

Access reports, sampling instructions, troubleshooting tips, and more all through the Trace Analytics website and AirCheck Academy. Download training documentation for your records.

View the status of your report, download current and past files, and manage who receives notifications in one portal.

Protect Your End Product

Compressed Air used in the pet food industry is just as important as it is in the human food or pharmaceutical industries. We wouldn’t want to unknowingly subject our pets to anything harmful.

Compressed Air can easily become contaminated if not monitored, properly maintained and the quality tested.

Other Testing Services for Manufacturers

Testing Made SimpleAccurateEasy

Trace Analytics’ laboratory is accredited by the American Association for Laboratory Accreditation. We use state-of-the-art lab equipment that allows us to analyze hundreds of compressed air and environmental samples daily. The result is consistency, accuracy, precision, and rapid turnaround. Trace is an A2LA accredited laboratory complying with ISO 17025, certificate #0322-01.