Compressed air is used for a variety of systems in the animal and pet food manufacturing industry. Because this air both directly and indirectly impacts the feed and the manufacturing processes, it is important to consider compressed air as a critical factor. As with any critical factor, compressed air in the pet food manufacturing industry should be regularly monitored and tested to ensure quality.

Both the FDA and the BRC have several guidelines for compressed air quality as it pertains to pet and animal food. Demand for safer products and more natural food choices continues to increase among consumers. Individual pet owners, large-scale breeders, farmers, and ranchers all expect manufacturers to provide feed options that are safe and cost-effective. Regular compressed air testing can help ensure the feed is safe for the end user and helps to prevent recalls or shutdowns.

Regulating Bodies and Specifications for Pet and Animal Food

- FDA: In 2017, the FDA released FSMA-related rules that affect the human and animal food industries. FDA pet food regulations include preventative controls, supplier verification programs, accreditation of auditors and certification bodies and sanitary transportation (AFIA, 2017).

- AAFCO: The Association of American Feed Control Officials is a group of state and federal feed regulators that developed the definitions for feed labels alongside the FDA (AFIA, 2017).

- BRC: The British Retail Consortium created Additional Module 9 that covers food products that are supplied for use in farmed animal feed (BRC, 2018).

- SQF: Safe Quality Foods Edition 8 states that “Compressed air or other gases (e.g., nitrogen, carbon dioxide) that contacts animal feed or feed contact surfaces shall be clean and present no risk to food safety” (1995).

Common Contaminants that Affect Pet and Animal Food

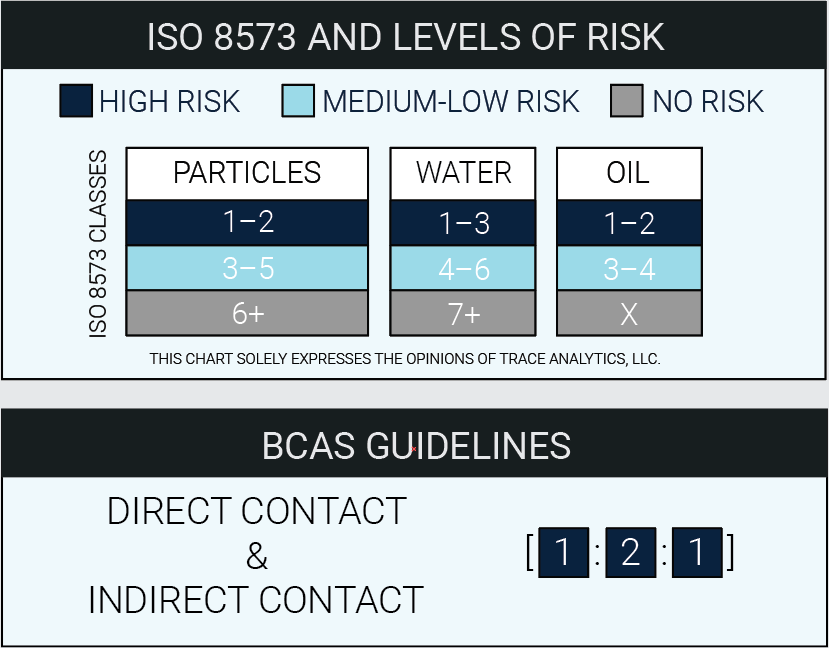

Human and animal food manufacturers alike refer to an industry standard for compressed air quality that is known as ISO 8573. When using this standard, or one of the above, contaminants like particles, water, oil, and microorganisms are to be tested for on a regular basis. Using specified quality standards can help ensure the quality of the air and protect the end user from potentially devastating effects.

Particles can have a negative impact both on the system and on the end user. Whether these particles are from a poor choice of materials or have resulted due to a lack of acceptable filtration, it is critical to catch the contamination.

Water contamination can cause degradation of the system and create a damp environment which is excellent for additional contaminants like microbes to affect your product and manufacturing system.

Oil contamination comes in a variety of forms, even if the system uses an oil-free air compressor. Oil Aerosol and Oil Vapor can result from cleaning solutions, old or ineffective filters, or sampling point lubrication.

Microorganism contamination must be carefully monitored as these contaminants can be particularly harmful to end users. According to FDA pet food regulations, canned foods, in particular, must be processed in compliance with the human food regulations in place that ensure that it is free of viable microorganisms (2018). Additionally, raw pet food poses an especially high risk of bacterial contamination, like Listeria and Salmonella. These bacteria can affect pets and their owners alike (FDA.Gov, 2018). As previously mentioned, the introduction of water to the compressed air system can create a habitat for microorganisms to prosper (Parker, 2014). The FDA reports countless recalls due to Salmonella contamination in pet food.

Manufacturing Risk Assessment and Hazard Analysis

Animal and pet foods are susceptible to recalls and require truthful labeling and safe practices. As with human food, a pet food recall or animal feed health risk can put manufacturers in a precarious position. The costs associated with a shut down are exponentially more than the costs of regular testing. With pressure from consumers for healthy and safe pet food, a recall can be hugely damaging to any company.

An important step in preventing contamination is to determine critical control points. Greater risks are associated with and must be accounted for if the animal food in question is raw, canned or includes medical drugs. Employing science-based risk assessment criteria ensures that animal food manufacturers are providing safe products at all times (IFIF, 2013). Codex Alimentarius, SQF, BCAS, and the FDA all point out the dangers that contamination, particularly microbial contamination, can present in pet and animal food.

Performing a manufacturing risk assessment and hazard analysis is a great way to set up a monitoring plan. Analyzing the main sources of potential contamination, the structure, and build of the system, and the use of compressed air (direct or indirect) can help a manufacturer choose the frequency of testing and the purity classes to meet.

Testing Your Compressed Air Quality

Because of the risks both to the end user and to the manufacturing process, it is critical to test your compressed air regularly. With the help of a third party accredited laboratory, sampling is a simple process. Trace Analytics provides a variety of testing services with the capabilities to test to whatever purity class your system needs to meet. Compressed air quality testing kits are available along with easy to understand instructions and helpful sampling videos.

Our team of experts is ready to answer your questions and help you get started with your air quality assurance program.

References:

“Animal Health Literacy – Avoid the Dangers of Raw Pet Food.” U S Food and Drug Administration Home Page, Center for Biologics Evaluation and Research, 2018, www.fda.gov/animalveterinary/resourcesforyou/animalhealthliteracy/ucm368730.htm.

“Codex Alimentarius.” The Global Feed Industry – IFIF, 2013, www.ifif.org/pages/t/Codex Alimentarius.

“Food Safety – About Additional Modules.” BRC Global Standards, BRC , 2018, www.brcglobalstandards.com/brc-global-standards/food-safety/additional-modules/about-additional-modules/.

“Institute for Food Safety and Health (IFSH).” FSPCA Materials | Food Safety Preventive Controls Alliance (FSPCA) | Institute for Food Safety and Health (IFSH), Illinois Institute of Technology, 2018, www.ifsh.iit.edu/fspca/fspca-preventive-controls-animal-food.

Parker. “Compressed Air: An Overlooked Source of Contamination in the Food Industry.” Food Safety Magazine, 2014, www.foodsafetymagazine.com/magazine-archive1/octobernovember-2014/food-safety-insider-rapid-micro-solutions/compressed-air-an-overlooked-source-of-contamination-in-the-food-industry/.

“Pet Food.” U S Food and Drug Administration Home Page, Center for Biologics Evaluation and Research, 2018, www.fda.gov/animalveterinary/products/animalfoodfeeds/petfood/ucm2006475.

“The Food Safety Modernization Act (FSMA).” Feed Industry Statistics, American Feed Industry Association, 2017, www.afia.org/fsma101.