Respiratory Protection has consistently been in the Occupational Safety and Health Administration’s (OSHA) annual top 10 most cited violations for at least the past decade. These violations could translate to adverse health effects, costly penalties, and time-consuming delays on day to day business. Employers can protect workers from hazardous air contaminants by testing respiratory equipment to meet OSHA’s Respiratory Protection Standard 29 Code of Federal Regulation 1910.134. This standard states that employers must establish and implement practices to ensure that respirators are maintained so additional health hazards are not presented to the user. Trace Analytics, LLC can support industrial companies with regular testing to ensure breathing air standards for respirators are met.

Workplaces with functions such as chemical manufacturing, shipyard terminals, mining, and paint/chemical spraying can all put workers at a high risk of exposure to respiratory hazards. Workers may face insufficient oxygen environments, smokes, mists, gases, vapors, and sprays. The health risks involved with exposure to harmful workplaces can be deadly. Effects of exposure can include cancer, lung impairment, loss of brain function, asthma, and other diseases. OSHA urges employers to go beyond the minimum requirements to create a culture of safety at work, which has been shown to reduce costs, raise productivity, and improve safety.

Air Respirators

There are two types of respirators: Air Purifying Respirators (APRs) and Atmosphere Supplying Respirators (ASRs). APRs remove contaminants from the ambient air by passing it through a purifying element such as a filter. ASRs provide clean breathing air from a source independent of the ambient atmosphere, such as airline or supplied-air respirators, self-contained breathing apparatuses, or a combination of the two. Dependent on the hazards and respiratory protection plan necessary, ASRs can provide more protection to workers. The assigned protection factor is the level of protection that a respirator is expected to provide when the employer implements an effective respiratory protection program as specified by OSHA. APRs can provide an assigned protection factor of 50-1,000 whereas ASRs can provide an assigned protection factor of 50-10,000. This blog focuses on the standards applied to ASRs. Breathing air for ASRs can be sampled and tested to ensure that it meets OSHA standards.

Breathing Air Standards

OSHA enforces its Respiratory Protection Standard under 29 Code of Federal Regulation 1910.134. OSHA references the following entities for breathing air standards:

- National Institute for Occupational Safety and Health (NIOSH)

- Compressed Gas Association (CGA) of the American National Standards Institute (ANSI)

- United States Pharmacopeia (USP)

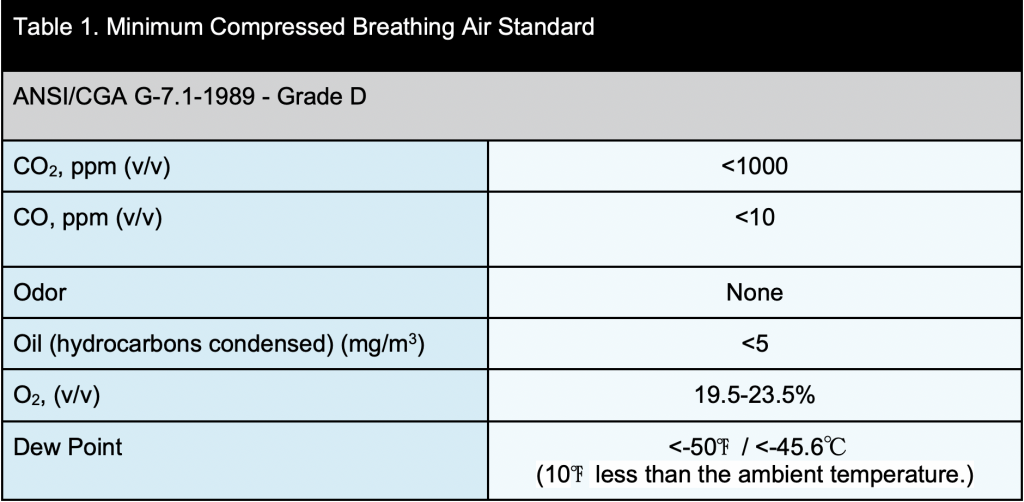

Before use, all respirator equipment must be certified by NIOSH. OSHA and NIOSH state that breathing air for ASRs must, at a minimum, meet Grade D requirements described in ANSI/CGA Commodity Specification for Air, G-7.1-1989 (Table 1).

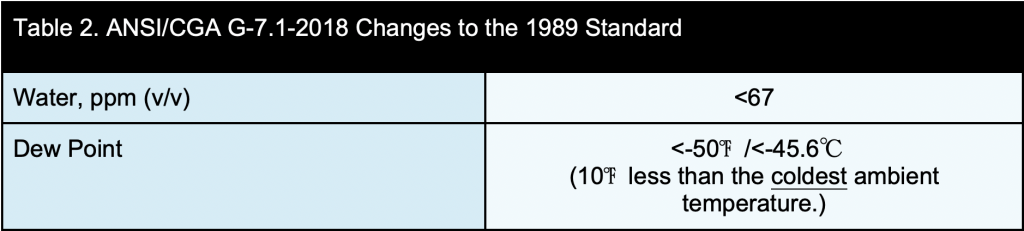

Since the implementation of the OSHA Respiratory Protection Standard, CGA G-7.1 has released a 2018 standard which minimally edits the CGA G-7.1-1989 version (Table 2). These changes to the 1989 standard are not enforced under the OSHA Respiratory Protection Standard and are higher optional standards for employers to consider.

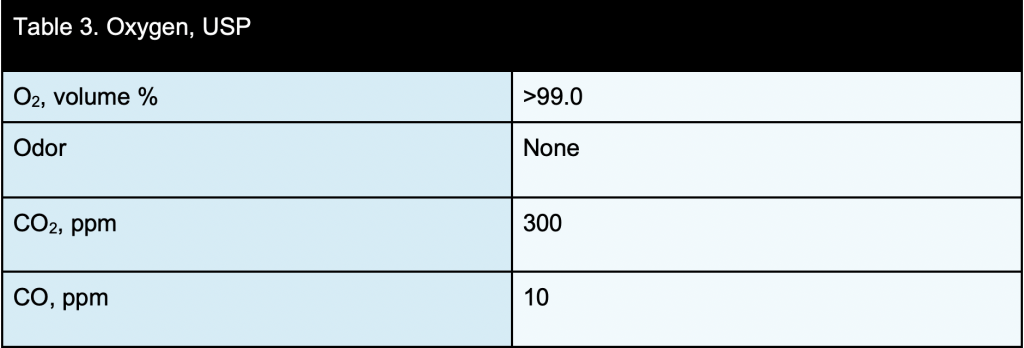

OSHA states that pure, compressed, and liquid oxygen should meet USP requirements for medical or breathing oxygen (Table 3). Pure oxygen that is produced using air-liquefaction is exempt from the requirements of the tests for carbon dioxide and carbon monoxide.

When implementing respiratory safety programs, employers can determine testing schedules based on usage and other workplace factors. Breathing air testing can be performed annually, quarterly, or as necessary to reflect changes in workplace conditions. It is recommended that testing should also be performed after maintenance, such as filter changes, line additions, or part replacements. The OSHA Respiratory Protection Standard states that employers shall ensure that cylinders used to supply breathing air to respirators have a certificate of analysis showing that the air meets the requirements for Grade D breathing air.

Regular compressed air testing is recommended to maintain supplied-air respirator quality that meets OSHA Respiratory Protection Standard 29 CFR 1920.134. Trace Analytics, LLC is an accredited laboratory with decades of experience in ensuring comprehensive analysis and compliance to CGA G-7.1 Grade D quality of breathing air supplied by respirators. Sampling is simple and a certificate of analysis is provided within 3-5 business days. Testing with Trace Analytics, LLC can provide valuable data to help industrial workplaces ensure the safety of their respiratory air. Reaching a goal of zero respiratory protection incidents can provide benefits of protecting the bottom line, increasing productivity, and eliminating worker injuries.