In our last blog on breathing air contamination, we discussed the dangers of Carbon Monoxide contamination. While CO is one of the most dangerous forms of breathing air contamination, it’s not the most common. That title goes to water vapor.

Where Does the Water Come From?

According to Parker Hannifin, up to 99.9% of the total liquid contamination in a typical compressed air system is water. When ambient air is compressed, the air temperature rises, causing an increase in water vapor retention. Your compressor creates a high pressure environment, “compressing” or squeezing the water vapor out of the air. Before leaving the compressor, the air is cooled which reduces water vapor retention and leads to water vapor condensation: liquid water.

Why is Water Considered a Contaminant?

Water vapor in compressed breathing air can be problematic for a variety of reasons. If the water condenses into liquid, it can then freeze in cold weather, creating a potentially dangerous blockage of airflow. High water content can also increase the risk of exposure to other contaminants, like corrosive particulates. Water vapor, water aerosol, and condensed water can be found throughout your breathing air system. Each of these lead to corrosion, potentially exposing the user to harmful material from within the system as well as reducing structural integrity. For this reason, even though ambient air can easily have 50,000 parts per million (ppm) of water, breathing air specifications that test for water have much lower limits. NFPA 1989, for example, specifies a limit of 24 ppm.

What Does a Water Failure Result Mean for My Compressed Air System?

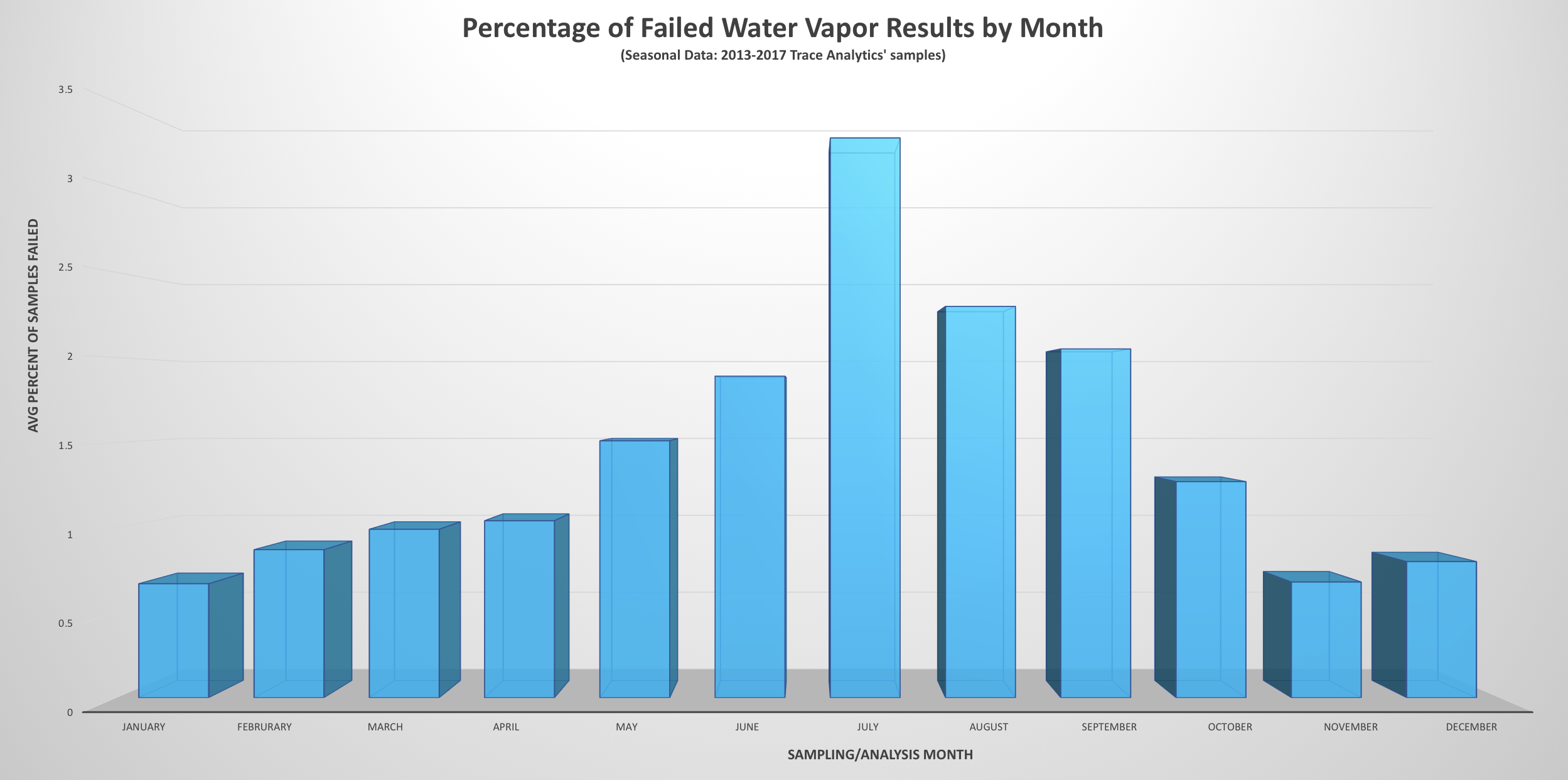

A failure for water vapor often indicates a problem with the compressor’s filter. Unlike Carbon Dioxide, water vapor failures tend to increase in the warmer months. Filters have a shelf life, but this life assumes a temperature of 70 degrees Fahrenheit. If the temperature at your inlet is warmer, your filter will deteriorate faster. Trace Analytics’ reports show failures occurring almost 5 times as much in July versus January.

If you’ve determined that your filter is not the source of your high water vapor result, there are other sources you can check. Your compressor drain removes condensation from your air system, but if the drain is malfunctioning or is not draining frequently enough, that water can end up back in your air. Long lengths of hose can accumulate and store water, particularly those greater than 10 feet in length. In this case, it’s best to take the sample from a shorter fill hose or directly from the compressor.

The backs of your AirCheck✓ Data Sheet and the AirCheck Academy both contain troubleshooting tips. These tips can come in handy, particularly if your on site detector tube readings indicate that your water vapor reading is out of spec. These detector tubes can be an invaluable tool, in allowing you to troubleshoot your compressor before you send in your sample. This speeds up the sampling and results process by allowing you to immediately take your free resample and send it in with your previous sample, rather than waiting to get the results for your first sample.

Do you have more questions?

Don’t worry – our knowledgeable customer service team is available to answer any questions.

References:

Sikes, David. “10 Contaminants Affecting Your Compressed Air System – Part One.” Parker Hannifin, 20 May 2016, blog.parker.com/10-contaminants-affecting-your-compressed-air-system-part-one.

United Kingdom, Anthony, T.G., and P.R. Clarke. Health and Safety Executive, 2006. www.hse.gov.uk/research/rrpdf/rr427.pdf. Report by QuintCo Limited for Health and Safety Exchange.